Gone are the days of hand-crafted prototypes and endless design revisions. Companies can produce accurate representations of their products in a small fraction of the time and expense.

3D modeling has changed the way companies design and create prototypes. It even provides designers and engineers with the tools they need to bring their ideas to life.

3D modeling offers a myriad of benefits that streamline the product development process. In this article, we’ll see how it has helped companies make prototypes. Keep on reading!

Improved Visualization

Companies can visualize their product, allowing them to make better design decisions. It allows the designer to see how different parts fit together and how the final product will look.

3D modeling also helps the design team identify potential design flaws. They can make corrections before the product goes into production.

3D modeling allows companies to create photorealistic images and animations of their products. They can use it for marketing and advertising purposes. They can showcase their products to potential customers before they are even manufactured.

Efficient Iterations

In the past, creating a physical prototype was a time-consuming process. It required the use of expensive materials and tools. With 3D modeling, designers can make changes to the design and create a new prototype in a matter of hours.

This is particularly useful when creating complex or intricate designs. The designer can test different variations to find the best solution. This saves time and money and also allows companies to bring their products to market faster.

Cost-Effective Prototyping

Creating physical prototypes can be expensive, especially if there are multiple design revisions. With 3D modeling, companies can test it and change it until it meets the desired specifications. This reduces the need to create a physical prototype until the design has been finalized.

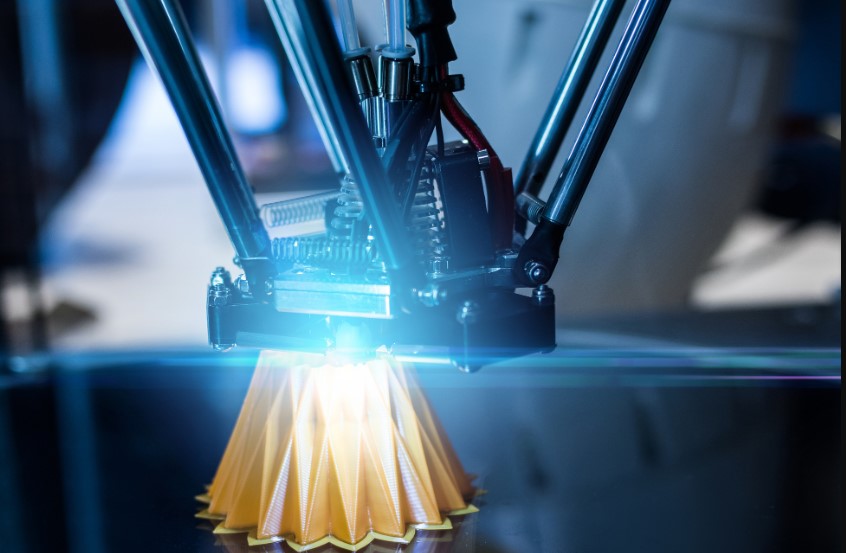

Also, 3D printing technology has made it possible to create prototypes using plastics, metals, and ceramics. Designers can test the functionality of the product before it goes into production. This then helps to save significant costs in the long run.

Enhanced Collaboration

3D modeling also enables enhanced collaboration between designers, engineers, and other stakeholders.

With 3D modeling, multiple team members can work on the same project simultaneously, regardless of their location. This saves time and resources when working on complex projects that need input from other team members.

Furthermore, 3D models can be shared and reviewed. This allows team members to give feedback and suggest changes in real time. Everyone can be on the same page while meeting the desired product specifications.

The Role of 3D Scanning

In addition to 3D modeling, 3D scanning technology has also helped companies make prototypes. It allows companies to create a digital representation of an existing object. Then they can use this as a reference when designing new products.

This is particularly useful when creating replacement parts or improving existing products. The designer can scan the existing object and make modifications to the design as needed. Also, companies can buy a used 3D scanner for sale, which can reduce the cost of acquiring this technology.

The Power of 3D Modeling to Make Prototypes

3D modeling has revolutionized the way companies design and make prototypes. It has made the process faster, more efficient, and cost-effective.

Designers and engineers can make adjustments and improvements before physically creating a prototype. This has led to reduced lead times, minimized errors, and increased customer satisfaction.

So what are you waiting for? If you would like to stay ahead of the curve, visit our page today to learn more tips!